Duy Tan has recently expanded its manufacturing capacity with the launch of Injection Workshop No. 2, covering an area of 2,100m² at the Duy Tân Long An Factory (Tan Do Industrial Park, Duc Hoa, Tay Ninh). Equipped with state-of-the-art machinery, the new workshop is positioned to become a high-quality packaging production hub that meets international standards.

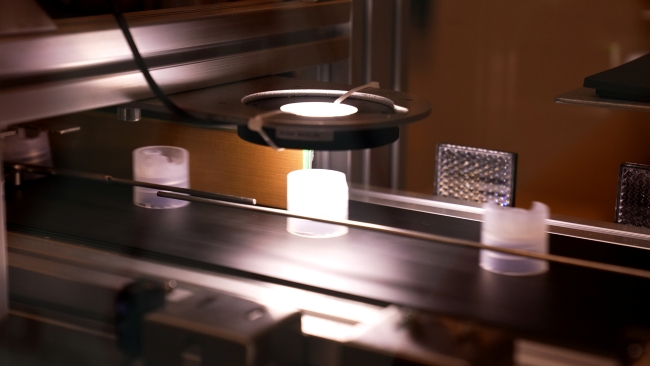

At Injection Workshop No. 2, Duy Tan has invested in JSW (Japan Steel Works) injection molding machines—Japan’s leading technology—along with an automatic cap assembly line integrated with leak-testing systems and AI-powered defect detection cameras. With a capacity of 10,000 products per hour, this marks a significant milestone in automation and smart technology application at Duy Tan.

Injection Workshop 2 spans a total area of 2,100m².

Japanese technology injection molding systems installed at Injection Workshop 2

The workshop also features a fully upgraded and synchronized technical infrastructure, including pallet cranes, piperacks, electrical systems (power stations and electrical cabinets), elevators, IT systems, cold rooms, cooling towers, and a central chiller system imported from the U.S. All operations comply with international quality management standards such as ISO and BRC, ensuring optimal and consistent product quality.

Cold room area.

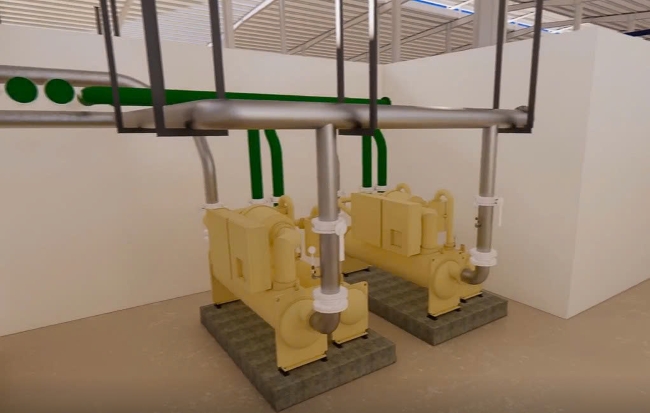

Cooling tower area (3D model).

Vertical air-conditioning system area.

Compressed-air chiller area.

With its advanced equipment and stringent quality control, Injection Workshop No. 2 enhances packaging quality, optimizes production capacity and speed, and enables Duy Tan to flexibly meet growing customer demand across diverse markets. This investment significantly strengthens the company’s production infrastructure, ensuring the ability to deliver internationally standardized products and services while expanding both manufacturing capacity and global reach.

Cap production line at the injection workshop.

Duy Tan expects this model to serve as the foundation for future large-scale production projects and collaborations with global partners—an important step toward becoming a Global Supplier ready to serve international orders.

The injection workshop is equipped with advanced technologies.

Over the years, Duy Tan has continuously invested in expanding factories, enhancing R&D capabilities, and accelerating automation and robotics adoption. In addition to Japanese technology, the company has also deployed advanced production lines from Germany, Italy, and Taiwan, forming a tightly controlled, end-to-end manufacturing system aligned with sustainable standards across the supply chain.

Through its future expansion plans, Duy Tan reaffirms its commitment to “Invest in Production – Innovate Continuously – Serve Customers Better.” This also aligns with the company’s sustainable development strategy following its integration into SCG Packaging (SCGP) - ASEAN’s leading packaging solutions provider since 2021.